Transport

WARNING

Suspended loads!

Danger of (serious) injuries caused by falling parts.

- Standing under suspended loads is prohibited!

- Do not move loads over workplaces where persons are present!

NOTICE

Only use properly functioning hoisting and lifting gear!

Only use properly functioning hoisting gear to lift and lower the mixer. Screw the lifting eyes needed for attachment to the motor plate. Ensure that the mixer is not damaged during lifting and lowering. Do not exceed the maximum permissible bearing capacity of the lifting equipment. Check that lifting equipment is functioning properly before use!

CAUTION

Material damage due to incorrect transport.

The hub and propeller blades can be damaged when the mixer is lifted.

- When lifting the mixer, place foam padding (min. 20 mm/1 in thick) beneath the hub.

- Never set the mixer down on the hub during transport.

- Wear protective equipment! Observe the work regulations.

- Safety shoes: Protection class S1 (uvex 1 sport S1)

- Wear safety helmet (EN 397 Conforms to standards, protection against lateral deformation (uvex pheos))! Observe the factory regulations!

- Only remove the outer packaging at the site of use to ensure that the mixer is not damaged during transport.

- Only transport the mixer horizontally when on a pallet and using a forklift truck!

- Only transport the mixer vertically using hoisting gear and lifting slings!

- Use tear-proof plastic sacks of sufficient size to package used mixers for transport in a leak-proof manner.

- Package the drive unit in a water-resistant manner. Moisture ingress will lead to total failure! For further information, consult the manufacturer’s instructions.

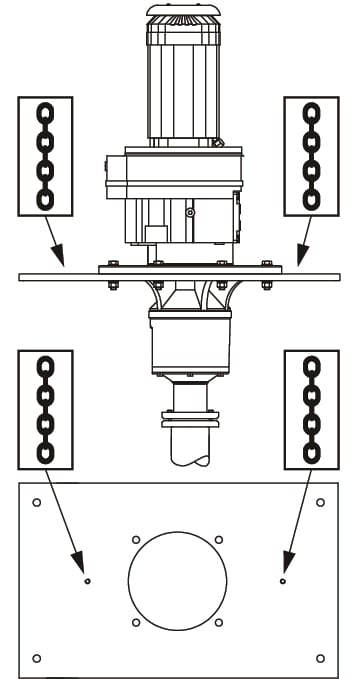

Attachment points

- Comply with applicable national safety regulations.

- Use lifting eyes permitted for angular loading up to 90° (e.g. “Theipa Point TP”)

- Up to 3 kW: M12 lifting eye

- 4 kW and over: M16 lifting eye

- Consult type key for motor power!

- Always screw two lifting eyes into the motor plate for horizontal transport.

- Use legally specified and approved lifting gear.

- Select the lifting gear based on the prevailing conditions (weather, attachment point, load, etc.).

- Only attach the lifting gear to the attachment point. Fix in place with a shackle.

- Do not stretch lifting gear over the drive unit. If necessary, use a load bar!

- Use lifting equipment with sufficient bearing capacity.

- The stability of the hoisting gear must be ensured during use.

- When using hoisting gear, ensure a second person is present to coordinate the procedure if required (e.g. if the operator’s field of vision is blocked).