Installing the mixer

CAUTION

Material damage due to excessive bending stresses!

If the mixer shaft is not installed perpendicularly, it may be subjected to high bending stresses. These bending stresses can damage the mixer shaft and the gear. To ensure perpendicular installation of the mixer shaft, install the motor plate precisely using equalisation sheets.

Affix the drive unit, with the mixer shaft and hub mounted, to a suitable support structure. Once the mixer has been installed, attach the propeller blades.

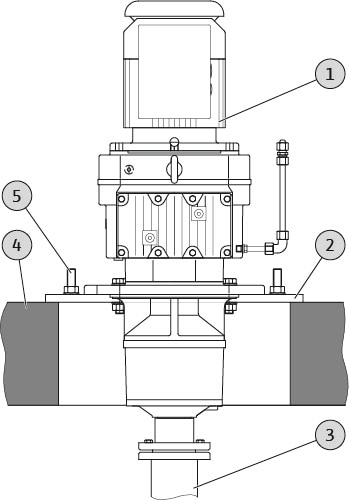

1 | Drive unit |

2 | Motor plate |

3 | Mixer shaft |

4 | Support structure |

5 | Motor plate fixation |

- Slinging point installed on the motor plate.

- Work area demarcated and free of any other objects or contaminants.

- Ensure work is carried out by two persons.

- Fasten the hoisting gear to the slinging points.

- Slowly lift the mixer.

- Position the mixer over the support structure.

- Slowly lower the mixer.

- Make precise positioning adjustments by hand while lowering.

- Lower the mixer until the motor plate rests completely on the support structure.

- Check perpendicular alignment of the mixer shaft. If necessary, adjust the motor plate with equalisation sheets.

- Affix the motor plate to the support structure. Tightening torque according to assembly drawing!

- Detach hoisting gear.

- Mixer is installed. Prepare and attach propeller blades.