Oil change in seal housing (TR 30-1/40-1, TRE 30/40)

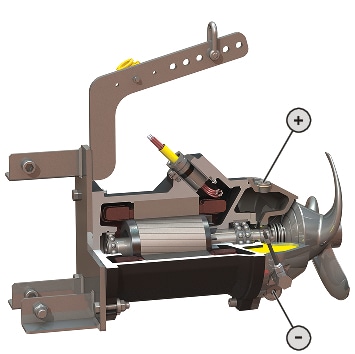

+ | Fill oil in the seal housing |

- | Drain oil in the seal housing |

- Protective equipment used!

- Mixer removed, cleaned and disinfected.

- Place mixer on a firm work surface in a horizontal position.

- Secure the mixer against falling over and slipping.

- Position a suitable tank to collect the operating fluid.

- Unscrew the screw plug (+).

- Unscrew the screw plug (-) and drain the operating fluid.

- Check the operating fluid:

- Operating fluid clear: Operating fluid can be reused.

- Operating fluid contaminated (black): fill with new operating fluid.

- Operating fluid milky/cloudy: Water in oil. Minor leakage through the mechanical seal is normal. If the ratio of oil to water is less than 2:1, the mechanical seal may be damaged. Change the oil and check again four weeks later. If water is again present in the oil during the second check, contact customer service!

- Metal chips in the operating fluid: Contact the customer service!

- Clean the screw plug (-), replace the seal ring and screw it back in. Max. tightening torque: 8 Nm (5.9 ft·lb)!

- Pour new operating fluid in through the hole for the screw plug (+).

- Comply with the specifications for the operating fluid type and quantity.

- Clean the screw plug (+), replace the seal ring and screw it back in. Max. tightening torque: 8 Nm (5.9 ft·lb)!

- Restore corrosion protection: Seal screw plug, e.g. with Sikaflex.