Dismantling/installing the control module

Take into account the “Shutdown” section before dismantling/installing the control module!

DANGER

Risk of fatal electrical shock! Generator or turbine operation during pump flow!

Even without the module (without electrical connection), there may be dangerous contact voltage at the motor contacts.

- Avoid flow in the pump during dismantling/installation work!

- Close the existing shut-off devices in front of and behind the pump!

- If no shut-off devices are fitted, drain the system!

- Do not place any objects (e.g. nail, screwdrivers, wire) in the contact area of the motor!

WARNING

Personal and material damage!

Incorrect dismantling/installation can lead to injuries and damage to property.

An incorrect module will cause the pump to overheat.

- In case of module replacement, ensure correct assignment of pump/control module!

Dismantling the control module

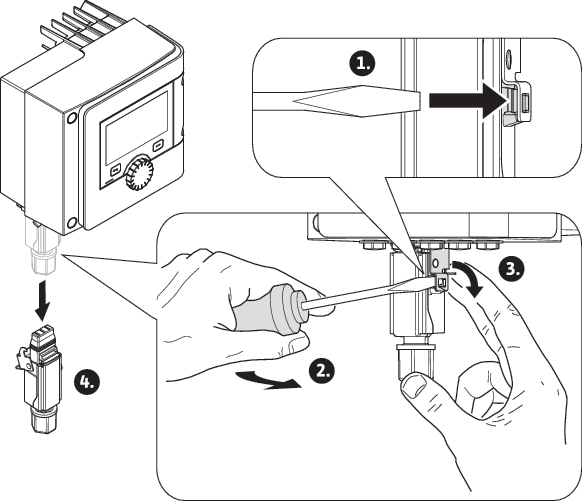

- Loosen handle grip of the Wilo-Connector using a screwdriver and pull out socket.

- Carefully remove sensor cable/double pump cable from the control module.

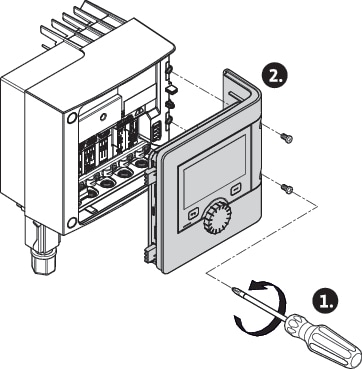

- Loosen the screws of the module cover.

- Remove the module cover.

- Disconnect all positioned/connected cables in the terminal room, undo the shield clamp and nut of the threaded cable gland.

- Pull out all cables from the threaded cable gland.

NOTICE

To loosen the leads: Open the WAGO “Cage Clamp” spring clip! Then pull out leads!

- If necessary, undo and remove the CIF module.

- Loosen interior hexagonal head screws (M4) in the control module.

- Remove control module from the motor.

Installation of the control module

The control module is dismantled in the reverse sequence of installation.